Thermoconcept Systems Prefabricated Rig Enquiry Form

This form is designed to make life easy for you.

Simply complete and email to Thermoconcept at enquiries@thermoconcept.co.uk and we will initiate preparation of a proposal to suit your requirements.

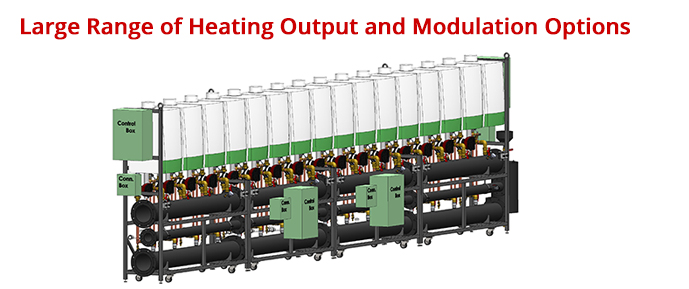

Complete the enquiryLarge Range of Heating Output and Modulation Options

Using the modular design ability with most modern boilers, the Thermoconcept approach lends itself to almost any required heating output by way of multiple unit installations for larger commercial or industrial applications.

With the increasing application of renewable and low carbon technologies customers are looking towards solutions using a combination of heat sources (ie multivalent solutions), A Thermoconcept pre-fabricated system can deliver these solutions in a single assembly.

The Thermoconcept pre-fabricated system approach is perfect for decentralisation programmes now happening in many commercial installations such as hospitals and universities where one large commercial boiler is being replaced.

From initial purchase through to installation, running and maintenance, the Thermoconcept solution saves money, time, valuable space and aggravation.

BIM Ready - Documentation

With each rig, whether standard or bespoke, a full documentation pack is provided including dimensioned drawing, hydraulic schematic and electrical wiring detail.

The documentation can be provided in hard copy or electronic form for easy incorporation into BIM (Building Information Modelling).

At enquiry/order stage CAD/PDF drawing are generally provided within 5 working days for your approval and comment.

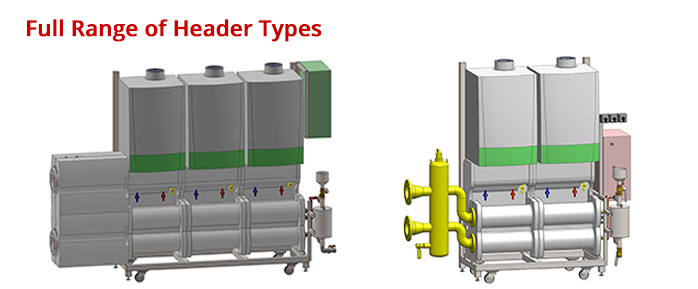

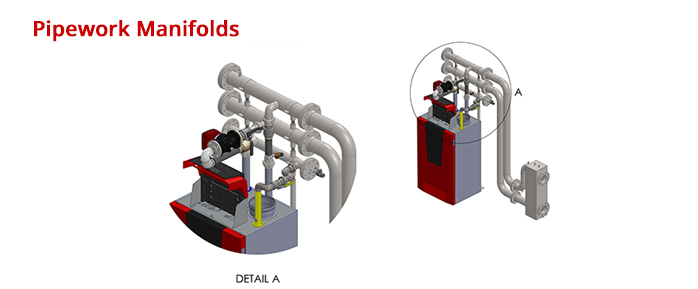

Full Range of Header Types

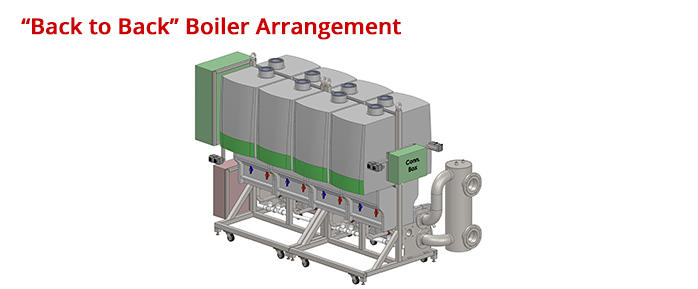

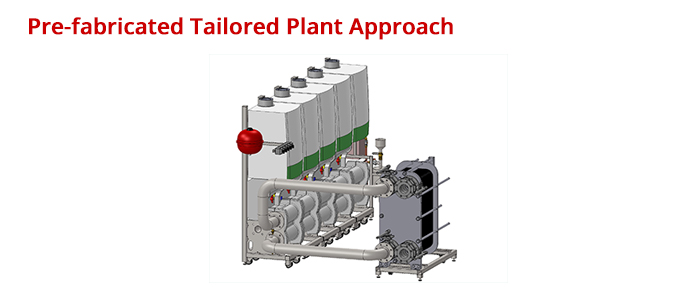

The Thermoconcept prefabricated plant rigs are designed as complete heating plant packages for rapid site installation and commissioning.

Generally the units are pre-piped to a single balance header with tappings of size, position and quantity to suit site specific zone requirements.

Using this pre-fabricated plant rig approach, any system is controlled to ensure optimum matching of boiler and renewable output to load at any given time. In addition, with multiple devices and/or heat sources individual units can be taken off-line for servicing with minimal impact on system performance.

- State-of-the-art controlled plant room system ready to go

- Supplied complete with full documentation pack

- Wall mounted variants available for floor space constrained situations

- Floor standing rigs available for up to 20 boilers

- Containerised plant rooms available as a housed solution

- A wide range of boiler make and models accommodated

- Comprehensive control module with extended options

- Incorporation of renewable heat technologies available

- Bespoke header arrangements available

- Biomass modules accommodated

- Renewable and multivalent integration

Gas Boiler Basic Rig Systems

Although almost any made to order requirement can be provided, Thermoconcept also offer a range of core Gas Boiler Basic Rig Systems for standardised plant rooms or as the starting boiler for a clients customisation.

The incorporated equipment is pre-piped and pre-wired ready for immediate connection within the plant room.

The balance header includes tappings for air vent, fill point/expansion vessel, drain off and system flow and return. The number and size of system tappings is as per the customers' own specification.

The basic Thermoconcept Rigs include:

- Up to eight wall hung commercial boiler units, as specified by the customer

- Individual shunt pumps within each unit (if not incorporated within the selected boiler)

- Single Balance Header sized according to output

- Comprehensive Controller

- Safety Valves (3 bar sealed system)

- Isolating Valves

- Drain Points

Advanced DHW Storage and Instantaneous Generation Options

In today's complex design approach it's common to have systems which require a number of different flow temperatures such as underfloor heating, weather compensation, DHW via indirect cylinder, air handling units, etc, the Thermoconcept plant rig approach can solve this problem by incorporating diverter valves to selected boiler(s).

In this way the selected boiler(s) can be "borrowed" from serving the main system flow to serve another requirement at another flow temperature. Once this requirement is satisfied the selected boiler(s) is diverted back to join the other boilers serving the system at the main flow temperature.

Whilst the boiler(s) is being "borrowed" the rig controller automatically increases the power demand from the remaining boilers to compensate.

This can be repeated with other boiler(s) at other temperatures to meet user requirements.

Multi-valent System Solutions

As renewables and LZC measures grow in the scope of their application, market demand and regulatory requirements it is becoming increasing common to use alternatives to more traditional gas boiler heat sources either as a replacement for gas boilers or a supplement.

Thermoconcept Systems can incorporate renewable and LZC measures, such as biomass and heat pumps within the plant rig solution. Multivalent system requirements can be accommodated with controls and hydraulic solutions to suit.

Bespoke Control Panel Options

Thermoconcept Systems can accommodate clients preferred control solution. The rig can therefore be considered as a complete plant room package for rapid installation.

In the event no specific control system is specified preferred, Thermoconcept have a range of highly flexible standardised modulating control systems to meet requirements.

Controls can be supplied as self contained or panel mount according to requirements.

Containerised biomass & gas boiler system

Thermoconcept Systems bring a new meaning to plug and play plant room solutions. Ourplant room approach incorporates biomassor gas boiler(s), fuel store, fuel delivery auger and controls. If requested, can also be installed buffer tanks, expansion vessels, low loss header or plate heat exchanger.The collectors are customised to accommodate any system connections.